The benefits of Light Emitting Diodes (LEDs) lead many facility managers to consider swapping their linear fluorescent fixtures to LED. Retrofitting linear fluorescent fixtures with tubular LED lamps (TLEDs) can provide several energy-efficient advantages. TLED units also cost less than a total lighting retrofit, but as lighting technology continues to evolve, these options are raising questions industry-wide. Understanding the available options and compromises is vital to managing expectations and achieving desired goals.

In this article, we’ll discuss the different types of TLEDs, the advantages and disadvantages of each, and examine concerns associated with TLEDs.

Types of TLED Retrofits

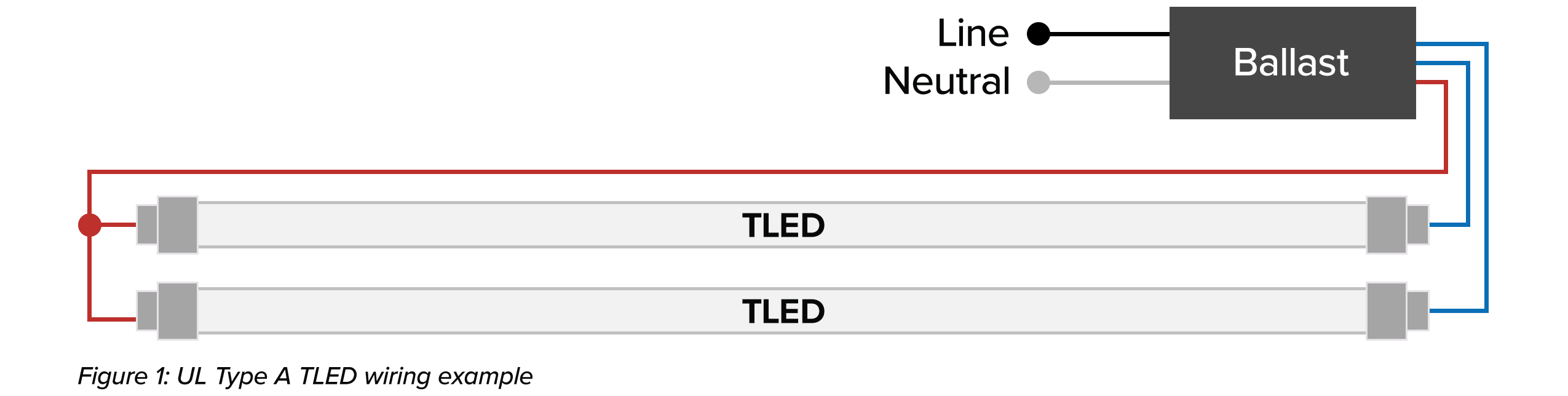

UL Type A: Retrofitted with Existing Fluorescent Ballast

Type A TLEDs are outfitted with an internal driver which allows them to work with existing linear fluorescent ballasts. However, potential compatibility issues between new tubes and existing ballasts should be evaluated to ensure good system performance. Nearly all manufacturers suggest reviewing their list of compatibilities prior to installing Type A LED tubes. Sometimes the LED lamp product isn’t even compatible with ballasts from the same manufacturer.

Some Type A tubes only function with instant-start (not rapid or programmed) ballasts, even if the ballasts are electronic, while others work with all starting modes. For many building operators, having a mix of electronic ballasts throughout their facility—with no record of the type in each fixture—is the norm. Facility managers should choose Type A TLEDs that are compatible with all starting modes in this scenarios.

Advantages of Type A LED Tubes:

- Lowest installation cost

- Quickest and easiest to install

- Plug & play!

- More and more products available

- Upgradable to Type C with external driver

Disadvantages of Type A LED Tubes:

- Ballast compatibility issues impacts performance; start-up, humming/buzzing noise, flicker

- Arcing concerns/electrical and safety issues

- System longevity depends on ballast

- Dimming and controllability limited by ballast

- Lower system efficiency due to energy losses in ballast

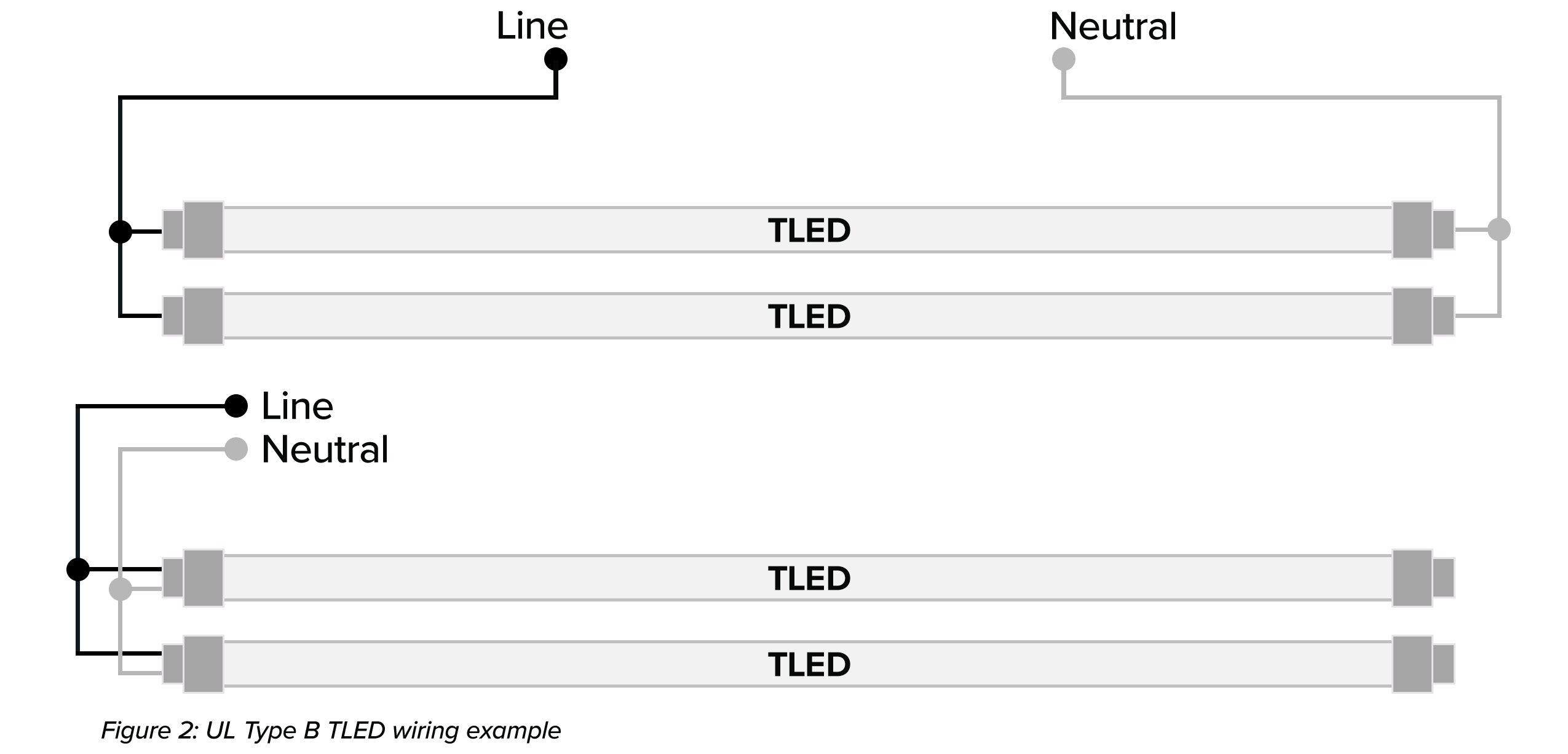

UL Type B: Wired Directly to Mains Voltage

Type B TLEDs also supply their own internal LED drivers, but instead of running on the stepped-down voltage from fluorescent ballasts, run on line voltage power. The existing ballasts are bypassed so compatibility (a concern with Type A) is not an issue. Single-ended Type B units may require the removal of the ballast and direct wiring of the socket to the line voltage. Potential risks of rewiring include the possibility of lamp failure, sparks, and potentially fires. Single-ended lamps may have been selected to reduce maintenance time, in the past, but as more and more facility managers realize their large safety risk, the industry has pivoted towards double-ended lamps.

Double-ended (DE) Type B LED tubes alleviate many of the safety concerns because there is no longer a way for the electrical current to travel across the lampholder—including situations where you install a fluorescent lamp. Also, due to the dual-end nature of Type B lamps, you no longer have to replace shunted sockets for non-shunted.

One of the major pitfalls of the double-ended Type B lamps is that they are very limited in lumen output options—with typically only two light levels available. Another pitfall of Type B LED lamps is the potential for flicker. Flicker was a common issue with T12 and was virtually eliminated by T8 solutions. It has returned with Type B TLEDs, but it is not prevalent in Type A or Type C units. In many cases, flicker goes unnoticed by many, but for certain segments of the population it can be extremely debilitating.

Advantages of Type B LED Tubes:

- Overall system simplicity

- Eliminate ballast compatibility concerns

- Avoid ballast failure and replacement

- Excellent efficacy and maintenance savings

Disadvantages of Type B LED Tubes:

- Highest installation cost

- Requires rewiring/ballast bypass

- Double-ended input w/ mechanical switches can create loose lamp connections with sockets

- Double switch type are more difficult to install

- Additional safety precautions

- Majority have no dimming capabilities

Type B Rewiring Concerns

In should be noted that, for years, concerns were raised over how rewiring might violate fixture UL listings, which could impact both safety and fire insurance liabilities. Many utilities refused to offer rebates for Type B TLEDs for this reason. Tom Lichtenstein of UL clarified the issue in July of 2017, stating ‘if the Type B unit has a UL label, the UL of the fixture in which it is installed, according to the TLED’s instructions, in not violated.’ After this clarification, some utilities that were previously not rebating Type B units now do so.

In order to avoid safety issues—if an attempt to install a fluorescent lamp in a converted fixture at a later date—UL requires labels that accompany Type B TLEDs be affixed to those fixtures as a warning to custodians not to do so. The label should also indicate whether a single-ended or double-ended TLED should be used in the re-wired fixture.

Type A/B “Hybrid” or “Dual Drive” TLEDs: Supplied with Dual Mode Internal Driver

Type A/B units are considered “hybrid” because they can be installed as a Type A “plug and play” unit using a fluorescent fixture’s existing ballast, but—if a ballast eventually fails—continue operating as a Type B unit (with appropriate rewiring).

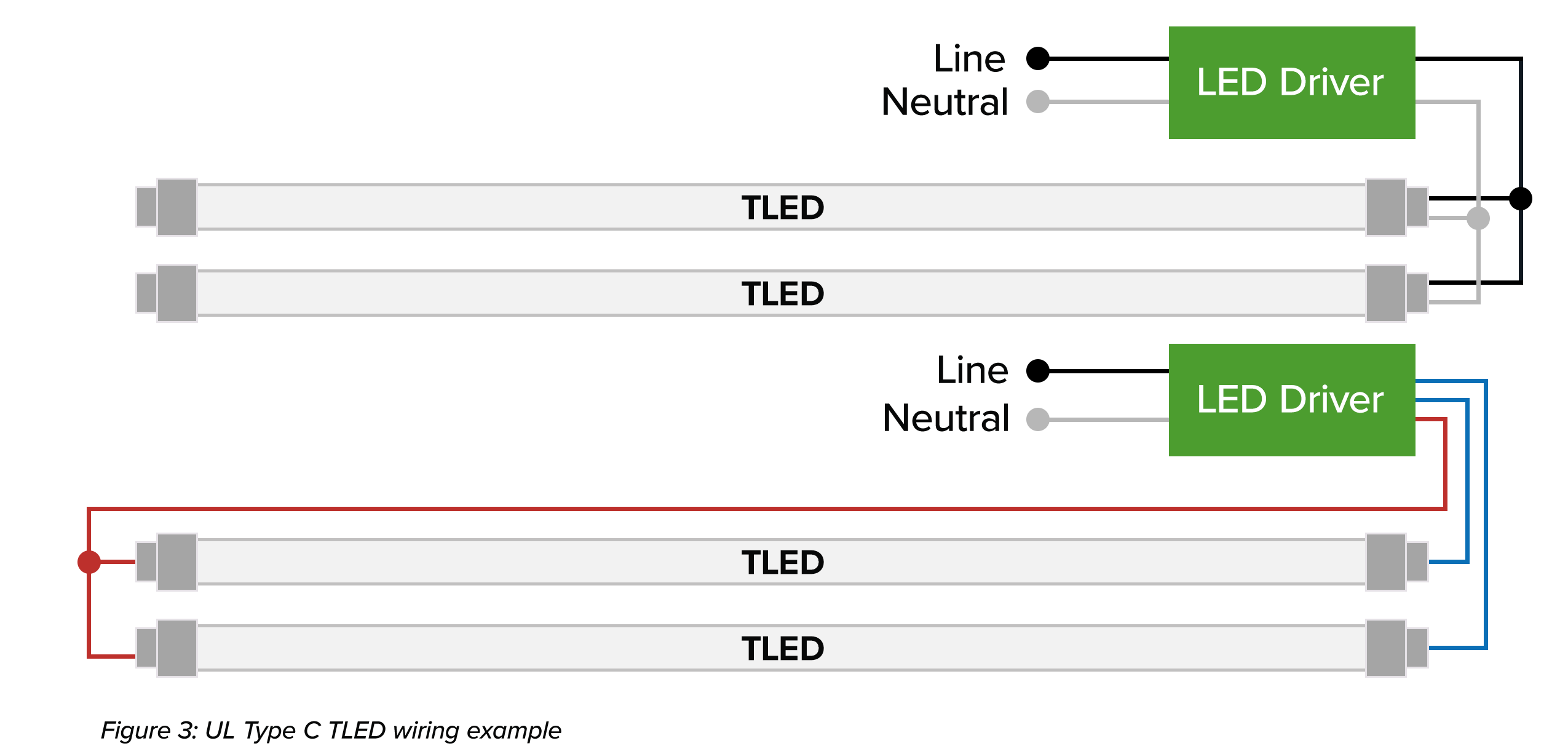

UL Type C: Supplied with Dedicated Drivers

Type C TLEDs also bypass existing ballasts, and are similar to LED fixtures in that you have a light engine and a separate driver. Type C units feature a fixture-mounted driver, unlike Types A and B, with drivers available with three different standard outputs, as well as being programmable for more or less output depending on required light levels. (It may be required to remove the fixture’s ballast to install the new driver.)

Low-voltage wiring runs from the TLED driver to the lampholders, avoiding the Type B line voltage issue, though the condition of the existing lampholders may still be an issue. It’s essential to adhere to the same UL requirements as Type B units (i.e. UL labeling of the unit, proper installation, adding warning labels) due to rewiring of the fixture. Installation may involve a bit more labor, and could potentially require the use of a licensed electrician.

Type C TLEDs typically provide the longest life and offer dimming capabilities other TLEDs do not. However, their higher price point often leads facility managers to look elsewhere. Type C units have their benefits, but similar to Type Bs, most of the market offerings do not capture the high lumen output category. Another potential issue with Type C lamps is that virtually none of the systems are cross-compatible across manufacturers—meaning you could be stuck with the manufacturer and product line they have installed in the facility—you would have a difficult time finding a lamp or driver from a different manufacturer that works with your existing system in the future if that system is discontinued, or the manufacturer goes under, resulting in an investment in a completely new system.

NOTE: Unlike fluorescent ballasts, which will power any appropriate fluorescent lamp, external TLED drivers are not yet standardized. If a driver needs to be replaced, the replacement driver will likely need to come from the manufacturer of the installed Type C TLED.

Advantages of Type C LED Tubes:

- Extended performance capabilities/highest efficiency

- Eliminate legacy ballast failure

- Controllable dimming system

- Programmable for various light levels

Disadvantages of Type C LED Tubes:

- Higher initial cost (requires LED driver), moderate installation cost, and time to install

- Tubes need to be compatible w/ driver; uncertainty that the new tubes will be backwards compatible

- More components to fail

- Locked into that manufacturer for replacement parts

How Much Could You Save By Switching to LED?

Concerns with TLED Retrofits

Efficiency

When considering how much electrical input power makes it to the LEDS, the three types provide different tradeoffs for the overall efficiency of the system. In Type A units, the line voltage must be converted to a regulated current and voltage by the ballast. The electronics of the lamp then have to re-regulate the current and voltage specifically for the LEDs. This double-regulation creates additional losses in the system as compared with Type B and Type C TLEDs. In certain scenarios, TLEDs will have to simulate the filaments in the end of a fluorescent lamp, typically causing additional losses and reducing efficiency.

Type B and Type C LED tubes, which use dedicated LED drivers, will typically have higher system efficiency than systems using Type A. (Biery, Casey 9)

Optical Quality

In all three TLEDs types, a common area of concern is the differences in optical characteristics between LEDs and fluorescents. The majority of TLED tubes do not have a light distribution pattern that matches fluorescent lamps. Specifically, most TLEDs do not emit light in an even 360 degree pattern as fluorescents do, and some TLEDs have a beam pattern as low as 105 degrees, causing fixtures using these lamps to disperse light differently, or to alter the amount of light available in the space.

The existing fixture reflector is designed to use light from all outgoing angles of a fluorescent lamp to distribute light evenly below the fixture. Outfitting the fluorescent lamps with a Tubular LED (which isn’t omnidirectional) can cause light distribution to become uneven, which, in-turn, can create non-uniformity on the work surface (e.g. desk, table, etc.).

Lastly, LED driver-quality is very important. Poor quality drivers (whether internal or external) can cause flicker that didn’t exist when fluorescent lamps were used. Since LEDs change their light output very quickly in-response to change in input current, any power fluctuations caused by a poor-quality driver will result in visible flicker. (Biery, Casey 9)

Product Lifetime

In many Type A situations, a TLED is used with a ballast that has already been installed for a significant portion of its expected life. If the ballast isn’t replaced simultaneously with the TLED that is being installed, the benefit of adding that long-life LED lamp is reduced from a maintenance standpoint. If the ballast fails before the lamp’s expected end-of-life, facilities personnel will have to get back up on a ladder, remove the lamps, remove the ballast housing and then replace the ballast. If a new ballast (or driver in Type C units) is installed at the same time as the LED lamp, there shouldn’t be any problems with system life, and maintenance costs are generally reduced over the lifetime of the fixture. (Biery, Casey 9)

Conclusion

To wrap up, choosing the right TLED retrofit solution means choosing the right balance for your facility—ease of installation vs cost vs performance. Beyond performance, safety should the overriding factor in any electrically-based operation. And while linear LED lamps are what’s popular at the moment, that doesn’t mean they’re the only option, or always the best option, when upgrading your lighting to LED.

You should always consult a lighting professional to ensure you’re aware of all the pros, cons and options available to make sure you meet all of your project goals. Schedule a no-cost facility audit today or give our experts a call at (608) 661-5555.